Guide for new business and research ideas

The project ideas reflect the capacity of the five partner organizations to promote research results for new project proposals, while including the contact data of the project’s responsible.

6. Presentation of the 30 project ideas in template

6.25. Development of Textile Materials as Vibration Isolators, VibraTex

|

Action |

Content |

|

Title of the project |

Development of Textile Materials as Vibration Isolators, VibraTex |

|

Envisaged Program for funding / other sources for funding |

Bilateral projects, Eureka, Horizon 2020

|

|

Domain of interest |

Universities, Textile Companies, Research institutes

|

|

Abstract (up to 500 words) |

The human body is frequently exposed to vibration from power tools and industrialmachines and from vehicles like trains and automobiles [1]. Vibration can cause discomfort, reduction of performance, inducement of activity interference and even health and safetyrisks. Human vibration involves the whole-body vibration (WBV) within frequencies 1–100 Hz when a person stands or sits on a shaking surface, and the hand-transmittedvibration (HTV) between frequencies 8–1000 Hz when holding a vibrating tool [1]. The effects of whole-body vibration include back pain, sciatica, digestive disorders, genitourinary problems and hearing damage. Long-term exposure to hand-transmittedvibration has a risk of developing hand-arm vibration syndrome (HAVS), a well-knownexample of which is vibration white finger (VWF). At present, preventive efforts have beenmade by using anti-vibration seat cushions [2] for WBV and gloves for HTV made ofdamping materials like polymeric foams, rubbers, gels and air bladders to reduce thevibration exposure. However, these materials suffer from insurmountable comfort andrecycling problems. Therefore, developing breathable and recyclable materials with goodvibration isolation performance is highly desirable.

The project aims to develop a range of 3D knitted/woven spacer fabrics made of polymeric fiber materials asvibration isolators by considering their spacer monofilaments asEuler springs, which have been proved to be excellent vibration isolators. The main variables considered for the experimental plan are:the monofilament diameter, different yarn inlay ratio, different spacer different machine gauge. |

|

Keywords (up to 5) |

|

|

Envisaged partners sought |

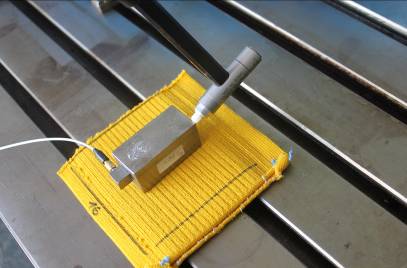

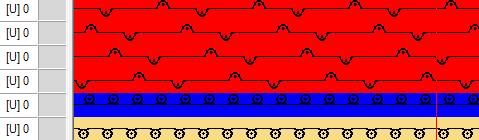

The main objective of this research is to experimentally investigate the vibration isolation behaviour of these fabrics with a vibrationtesting method, in order to understand how the fabric structural parameters and vibration testing conditions, affect their vibration isolation performance. Dynamic performance of the knitted fabrics are analysed by testing the behaviour of two metallic pieces, fixed one after the other on the sample, through an adhesive. The equipment used to excite the system, is an impact hammer Piezotronics type, and the natural frequencies were measured with an accelerometer PCB B52 Piezotronics (figure 1). The signal is processed with one data acquisition card 6023 National Instruments. The frequencies [Hz] are determined in three directions: coursewise, walewise, and perpendicular on the fabric surface. The frequency at the highest peak represents the natural frequency of the fabric.

Figure 1. Method of measurement of the natural frequencies [3]

The shape of the recorded frequencies curve reveals the capacity of the system to damp the vibrations, the smoother is the shape, and the highest is the fabric damping capacity. An ideal weft knitted spacer fabric developed for anti-vibration purposes, should have the capacity of absorb energy efficiently, still having sufficient stiffness to avoid its collapse and an acceptable thickness in order to maintain a sense of touch and dexterity to complete the tasks. It is expected that this research willboost the design of 3D knitted spacer fabrics for application in human vibration protection.

References:

[1] Mansfield NJ. Human response to vibration. London: CRC Press; 2005. [2] Lewis CH, Griffin MJ. Evaluating the vibration isolation of soft seat cushions using anactive anthropodynamic dummy. J Sound Vib 2002;253:295–311. [3] Blaga, M. et.al., Weft knitted spacer fabrics responseto vibrations 14th AUTEX World Textile Conference,May 26th to 28th 2014, Bursa, Turkey,

|

|

Contact data (Name/Surname, Organization, email) |

Prof. Dr. Eng. Mirela BLAGA, Ctext ATI Technical University “Gheorghe Asachi” from Iasi, Faculty of Textile-Leather and Industrial Management |